The Harvest Workshorse – “The Bruff” Hop Picker

As the end of August approaches, time will come where the valleys of Suckley are filled with the low rumble and hum of “The Bruff” Hop Picker. For us, it’s the sign of the start of the picking season, and the end of summer. Soon the bright, crowded hop yards will be empty for another year and the smell of hop drying will be filling the damp morning air.

“The Bruff” arrived at Stocks farm in the early 1960s. It didn’t have far to travel since it was manufactured here in Suckley, less than a mile away. Bruff Engineering manufactured the picker, which is a great example of brilliant British engineering. It’s simple and robust design continues to be widely regarded in the industry and they helped to revolutionise the industry by bringing in a reliable mechanical picking method – one machine replaced hundreds of people. The machines were so popular they travelled all over the world and there are still machines busily working away as far as Australia and New Zealand. The machines are so reliable; it’s said to be the main contributor to the decline of the Bruff Engineering business.

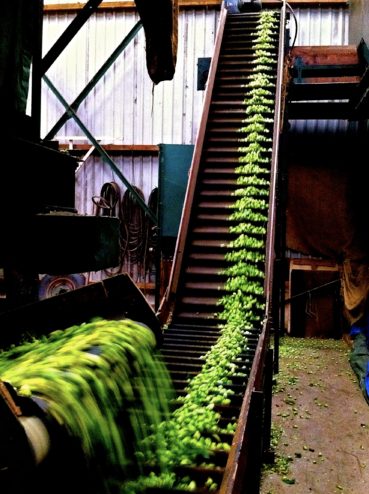

The ingenious way that The Bruff works is down to a series of different methods, working on the principle that the hops are heavier than the leaf and utilising gravity to separate them. The bines enter the shed from the field and are mounted upside down onto the track. From this point, the bines are stripped and the hops begin their journey. They travel along sticky belts, through rollers and past fans before finally going along the waterfall belt and up into the kilns to be dried. It takes 20 minutes for the bines to travel from field to kiln, with The Bruff processing a staggering 19 bines per minute. This process is noisy, but the hum of the harvester is a welcome sound during harvest. During hop picking, the hop shed is highly aromatic with a unique evocative smell coming from the freshly picked bines.

We’re so proud of our Bruff Picker that we repainted it for it’s 55th birthday. It remains one of the most efficient hop picking machines available and with no modern equivalents able to treat the hops in the same gentle way, we like to make sure ours gets plenty of love and attention before, during and after the harvest. It has annual maintenance including belt and chain changes, but doesn’t need much to keep it running as wonderfully as it has done since it was new. We are lucky to have one of the original engineers, Albert Philpin, supporting the maintenance on the machine. We also use Suckley Engineering when we need parts replaced, who are based at the original home of Bruff Engineering! With this local support and the tireless work of our staff, we know our Bruff has many more seasons ahead.

If you’re local to Suckley, listen out for the signature low rumble, which starts at the end of August. The familiar sounds, smells and sights of hop picking conjure memories from the past, and we feel very fortunate to be part of this amazing industry’s future. At Stocks Farm, we grow enough hops each year to make 46 MILLION pints of beer, so think of our hop harvest workhorse next time you’re drinking a great British pint, and raise your glass to “The Bruff.”